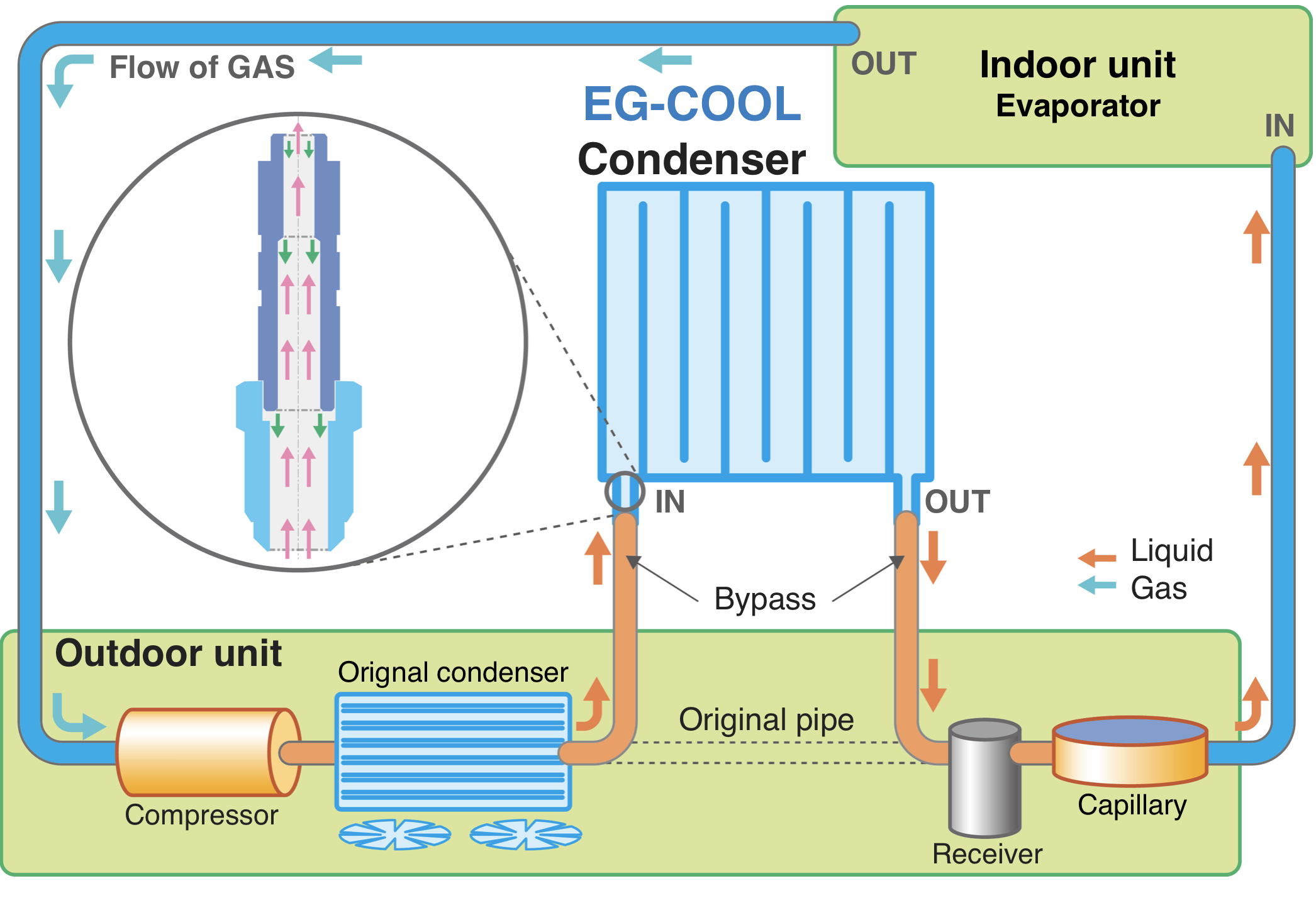

EG-COOL realizes energy saving effect by installing additional new condenser in existing air conditioner outdoor unit.

Structure of air conditioning is liquid refrigerant gas by an evaporator in indoor unit is heat-exchanged.

The warm air in the indoors is returned as cold air to the room by the evaporator to the refrigerant gas.

At this time, the liquid refrigerant gas is heated to hot gas and sent to the outdoor unit by heat exchange.

Refrigerant gas that has been sent hot gasification is compressed to high pressure and high temperature by a compressor inside the outdoor unit. State at this time of gas becomes semi-liquid

Refrigerant gas high pressure and high temperature compression from the compressor is sent to the condenser, then it is cooled to a medium temperature in the condenser.

Conventional air-conditioning systems isRefrigerant gas leaving the condenser removes impurities through the receiver, and it is sent to the capillary pipe, then It becomes liquid gas which is sufficiently cooled,

and then it is sent to the indoor unit, then, cold air is sent to the room by heat exchange at the evaporator of the indoor unit.

The capillary pipe has a capillary shape, it has the same role as the expansion valve. Heat energy is released by a capillary shape.

This capillary shape makes the flow in the pipe faster, then it is liquefied gasified, heat is released and it becomes cold air.

The Inverter technology is the latest evolution of technology concerning the electro motors of the compressors,

It is a control system that suppresses the movement of the compressor in the outdoor machine so that there is no useless movement.

By controlling the movement of the compressor, it is possible to demonstrate a significant energy saving effect.

Most of the power consumption of the air conditioner is the power of this compressor

By controlling the movement of the compressor it is possible to achieve energy savings of nearly 20% compared with conventional type air conditioners without inverters

So, the role of our EG - COOL as in the previous description is the hot gasified refrigerant gas that has been heat-exchanged in the indoor unit and sent to the outdoor unit is compressed at high pressure and high temperature by the compressor

This bypass system is EG - COOL (additional condenser system)and State will have a higher cooling effect liquefied refrigerant gas from the conventional condenser until towards the capillary pipe.

The characteristic of "EG - COOL" there is a condenser with two capacities,

① conventional condenser and

② with capillary pipe

for that reason it can send a high refrigerant gas having significant cooling effect on the capillary pipe, in comparison with conventional systems.

The role of EG-COOL is:

Before being sent from the conventional condenser to the capillary, it is sent to an additional condenser bypassing the conventional condenser,

As a result, efficiently cooled refrigerant gas can be sent to the capillary.

This highly efficient bypass system is the “EG – COOL” system.

Merit

As described above, Most of the power consumption of the air conditioner is the power of the compressor,

Therefore, an inverter type air conditioner for reducing the power consumption of the compressor was developed.

“EG-COOL“ will be able to easily bypass attached to the old conventional air conditioning system,

the energy-saving effect, we have achieved a very great energy-saving effect and the 25% to 35%.

We have demonstrated the reduction effect by attaching a simple meter when mounting the EG-COOL,

In addition, already proven energy-saving effect of 25% or more in Thailand of TOYOTA car factory

Even in the inverter type, we have demonstrated energy saving effect of more than 30% in Singapore.

note)Each energy saving effect depends on actual results and operation time.

As already mentioned, "EG-COOL" will be able to do with long life compressor.

Two benefits that extend the life of the power consumption and compressor brings a great advantage to the air conditioning of the user.